HD Thermal Break Strip

High Density Mineral Wool Isolation Strip for Cladding and Roofing.

PRODUCT

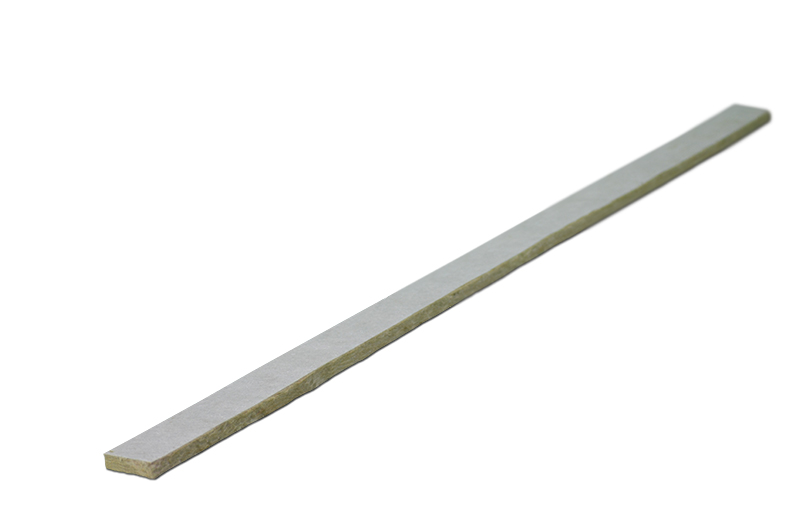

AIM HD Thermal Break Strip is manufactured from

high density rock wool strips faced on both sides with

glass tissue (alternatively Class 0 aluminium foil may

be specified as a facing).

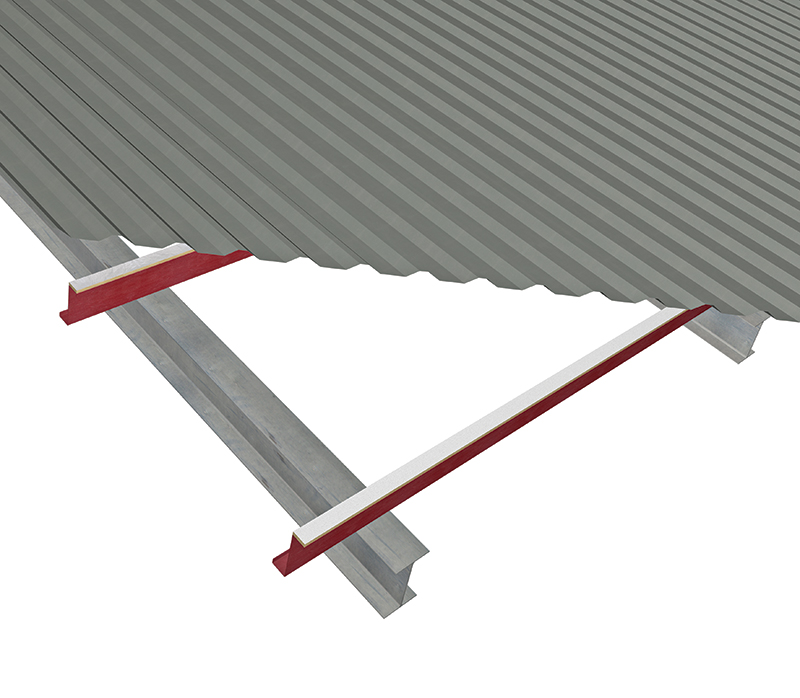

It is used in a range of applications to prevent cold

bridging.

AIM heavy duty spray adhesive is recommended to

locate the strip in position prior to fixing the cladding.

APPLICATIONS

The AIM HD Thermal Break Strip prevents cold

bridging and therefore condensation and heat loss

in buildings where the metal roof cladding does not

require thermal insulation. Typically such constructions

would be built from a steel frame structure with the

roof cladding supported by either

1) Liner Tray Systems

2) Metal Cladding systems using zed purlins.

The HD Thermal Break Strip can help reduce direct

sound transmission through the construction.

FEATURES

- High Density Rockwool strip.

- Tissue faced on both sides.

BENEFITS

- Prevents cold bridging and therefore condensation and heat loss.

- Can help reduce direct sound transmission through the construction.

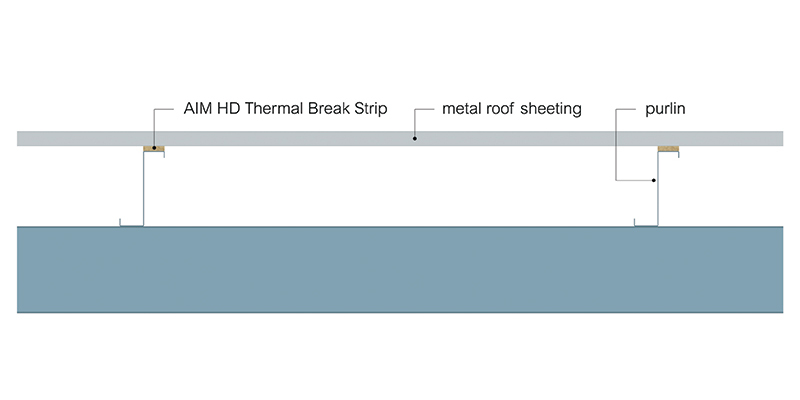

Example product installation schematic using materials by others

COMPONENTS available from AIM

- Spray Tack Adhesive

PHYSICAL INFORMATION

- Lengths: 1200mm

- Width: 50mm (or as specified)

- Thickness: 12mm (or as specified)

- Thermal Conductivity: λ = 0.040W/mK

PACKAGING

AIM HD Thermal Break Strips are generally packed into cartons and stretch wrapped onto wooden pallets with a showerproof polythene pallet cover and high quality edge protectors.

ITEMS REQUIRED FOR INSTALLATION

Personal Protective Equipment (PPE) required includes

- Abrasion resistant gloves

- Impact resistant goggles

- Dust mask

INSTALLATION GUIDELINES

The AIM HD Thermal Break Strip needs to be held in place whilst the roof cladding is secured as per manufacturer instructions. The best way to do this is to use a heavy duty spray adhesive applied 150mm from each end and in the middle of the strip. The AIM HD Thermal Break Strip is then placed along the top of the purlin or other supporting structure whilst the roof covering is fixed as per the liner sheet fixing instructions

STORAGE

Products are supplied in cartons on wooden pallets with edge protection and a shower proof hood. Products should be stored away from the elements until ready for installation.

MAINTENANCE

This product does not contain moving parts and, if undisturbed, requires no routine inspections or maintenance.

DURABILITY

AIM HD Thermal Break Strips are chemically inert, will not sustain vermin and do not encourage the growth of rot, fungi, moulds or bacteria. They are compatible with all normal building materials. They do not degrade under the usual conditions found in buildings and will perform effectively for the life of the building.

HEALTH & SAFETY

Insulation products supplied by AIM are considered

to be inert articles and as such are exempt from

requirements to provide a Safety Data Sheet.

A Product Safety and Handling Information Sheet is

available upon request.

ENVIRONMENT

Global warming potential = zero

For product recycling of stone wool based variants, please contact: Rockwool T: 01656 868400

E: [email protected] where the insulation used is Rockwool stone wool.

ORDERING

To order this product the following information will be required:

- Thickness and width of strip required.

- Approximate quantity in linear metres.

- Delivery location.

All AIM HD Thermal Break Strips are made to order. Products are typically supplied in seven to ten working days but lead times may vary depending on existing factory commitments.

There is no minimum order quantity or value although small orders may attract transport surcharges.

TECHNICAL SUPPORT

Technical Support is available from our experienced

sales team on 01293 582 400 or

[email protected]

Our Partners & Affiliates

AIM are partners with NBS. Our products can be found on NBS Source and have been authored to NBS specification standards and have both CAWS and Uniclass 2015 classifications.